Have any Questions?

Showroom

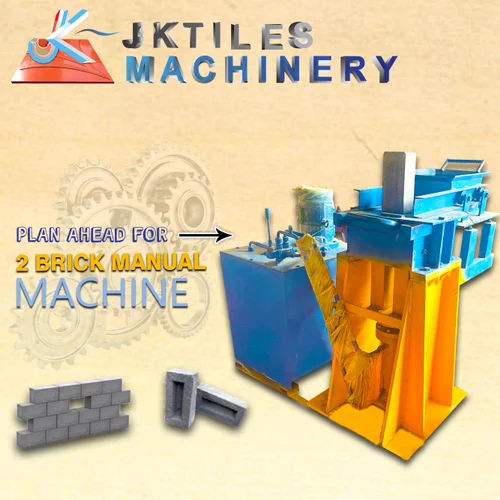

Block making machine is a

construction machine that produces concrete blocks that are thermally

insulated, water resistant, strong and uniform. The automatic machine produces

these blocks at a fast rate at a low operational cost.

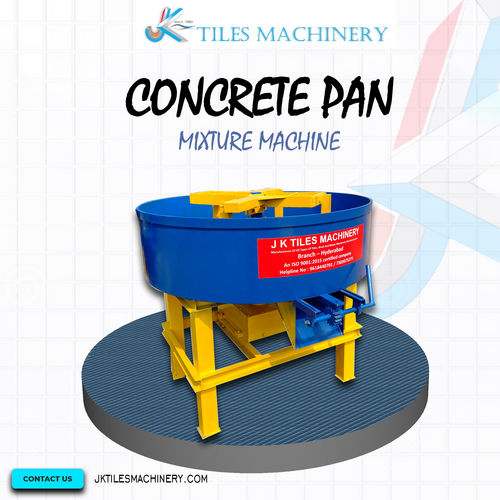

Cement and concrete tiles of different shapes and sizes can be

created using tiles making machine. The mixture can be created using a mixing

pan, while the entrapped air from the concrete on the vibrating table.

In the manufacture and production of fly ash bricks,

which are uniformly shaped, smooth, light, strong, and pleasing in color, the

fly ash brick making machine is used. The material utilized in the

production process are fly ash, cement, gypsum, quicklime, and water.

A tile hardener is a chemical added to the concrete mixture to

improve the strength, minimize the setting time of tiles, and enhance their

workability. The hardener chemical is supplied in bulk, packaged in large

drums.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese